What are the Benefits of Cold Spray Technology 2023?

In the ever-evolving landscape of technological marvels, Cold Spray technology has emerged as a game-changer, revolutionizing industries from aerospace to manufacturing. With a focus on versatility, efficiency, and cost-effectiveness, Cold Spray is leaving its mark on various sectors. Let’s embark on a journey to uncover the myriad benefits that this cutting-edge innovation brings to the table.

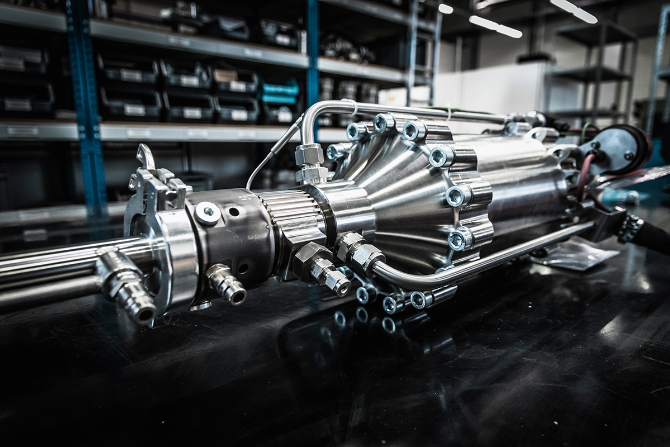

Understanding Cold Spray Technology

A Paradigm Shift in Material Deposition:

This technology emerges as a true marvel, seamlessly integrating scientific ingenuity with engineering finesse. This innovation challenges the norms of conventional material deposition techniques, carving a distinct path in the realm of surface enhancement and repair.

In a departure from traditional methods that heavily depend on elevated temperatures, Cold Spray harnesses the kinetic energy of fine particles accelerated to supersonic velocities, forming a robust bond upon collision with a substrate.

This process operates sans the detrimental effects of heat, preserving the integrity of even the most delicate materials. As industries seek precision, efficiency, and adaptability, Cold Spray stands tall, offering a realm of possibilities that transcend the limitations of its predecessors.

Enhanced Coatings

One of the primary benefits of this technology lies in its ability to create high-quality coatings. The impact of accelerated particles on the substrate creates a strong bond, resulting in coatings that are dense, uniform, and exceptionally adhesive. Whether it’s corrosion resistance for industrial equipment or wear resistance for aerospace components.

Material Efficiency

It takes a sustainable approach by reducing material waste. The absence of heat means that there’s minimal, if any, material oxidation or evaporation during the process. This translates to a higher material yield and cost savings, aligning with the growing demand for eco-friendly practices.

Aerospace Advancements

In the aerospace realm, Cold Spray is causing ripples of excitement. Its ability to create intricate geometries with minimal distortion is a boon for turbine engine components. As airlines strive for increased fuel efficiency, it’s lightweight and durable coatings contribute to enhanced aerodynamics and fuel economy.

Cost-Effectiveness

Cold Spray technology is rewriting the equation of cost-effectiveness. Traditional methods often involve high energy consumption and complex post-processing steps. Cold Spray streamlines the process, reducing energy costs and eliminating the need for extensive finishing, ultimately leading to quicker turnaround times.

Preservation of Heat-Sensitive Materials

Certain materials are exceptionally sensitive to high temperatures. Its’s unique approach allows these materials to be deposited without compromising their integrity. This opens doors to novel applications in industries where heat-sensitive components are prevalent.

Bridging the Generation Gap

In industries where skilled labor is retiring, Cold Spray offers a bridge to the future. Its automated and robotic integration capabilities make it an attractive option for next-gen manufacturers. The precise control it offers reduces human error, ensuring consistently high-quality results.

Limitless Innovations

As technology evolves, so does the potential of Cold Spray. Researchers and engineers are pushing boundaries, exploring its capabilities in new and exciting ways. From space exploration to medical advancements, this continues to shape the future.

Sustainable Growth

In a world increasingly conscious of its environmental footprint, Cold Spray’s sustainability resonates. Its reduced energy consumption, material efficiency, and extended component lifespans contribute to a more sustainable industrial landscape.

In conclusion, Cold Spray technology stands as a testament to human ingenuity. Its benefits extend beyond the surface, shaping industries and fueling progress. As we stand on the cusp of 2023, the future of Cold Spray is as promising as the coatings it creates – enduring, resilient, and transformative.

The Sustainable Advantages of Cold Spray Technology

Environmental Consciousness: In a time when environmental awareness is paramount, Cold Spray technology aligns perfectly with sustainable practices. Its energy-efficient operation and material conservation contribute to a reduced ecological footprint.

Energy Efficiency: Cold Spray’s remarkable feature lies in its reduced energy consumption. Unlike heat-intensive methods, Cold Spray operates at lower temperatures, leading to significant energy savings and promoting a greener industrial approach.

Material Conservation: The efficiency of Cold Spray translates to optimal material usage. With minimal waste generation and effective material bonding, it ensures that resources are utilized to their fullest potential, minimizing waste and promoting responsible resource management.

Extended Component Lifespan: Cold Spray’s unique metallurgical bond adds longevity to components. By restoring and enhancing parts with durable coatings, it diminishes the need for frequent replacements, ultimately reducing the consumption of raw materials and lessening the strain on the environment.

Transformational Progress: Cold Spray stands not just as a technological achievement, but also as a catalyst for progress across industries. Its multifaceted benefits have far-reaching effects, shaping manufacturing practices, advancing research, and fostering innovation that paves the way for a more sustainable and prosperous future.

Conclusion

In the dynamic landscape of technological innovation, the benefits of this technology in 2023 are nothing short of transformative. As industries navigate the complexities of efficiency, sustainability, and adaptability, Cold Spray emerges as a beacon of progress. Its ability to create enhanced coatings, reduce material waste, and extend component lifespans speaks to its impact on diverse sectors. The aerospace industry sees heightened aerodynamics, manufacturing embraces cost-effectiveness, and sensitive materials find preservation without compromise. Moreover, Cold Spray’s sustainable advantages resonate deeply, aligning with environmental consciousness and responsible resource management.